Certain vehicle components are designed to work together as precision-matched pairs. If these parts are interchanged or mismatched during maintenance, it can lead to serious performance issues and potential damage. Let’s look at which parts are at risk and how to ensure you keep them properly paired.

1. Why Should Diesel Engine Fuel System Components Stay Paired?

Problem:

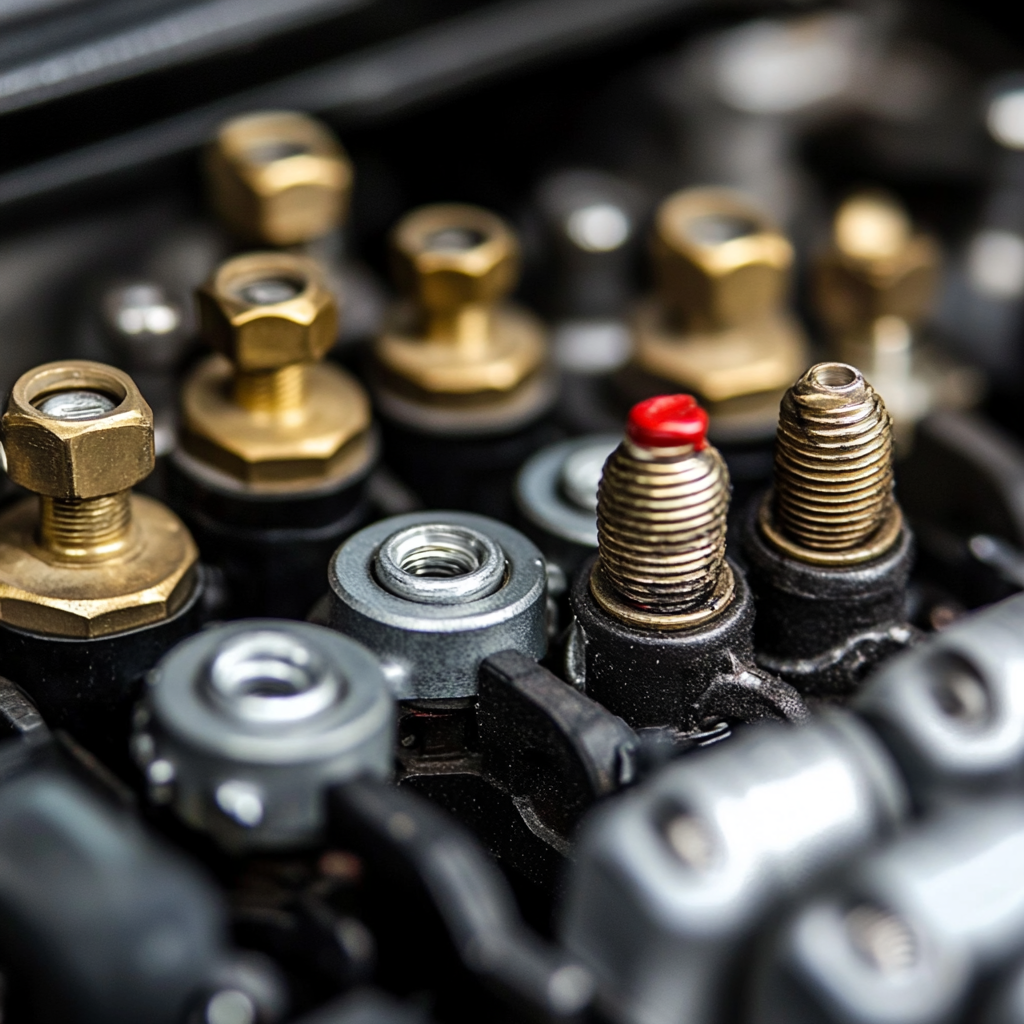

In a diesel engine, the fuel system's various components, such as injectors and precision fuel pump elements, are specially machined and finely ground in pairs during manufacturing. These components work in tandem with high precision, and any mix-up or interchange can lead to poor fuel delivery, inefficient combustion, or even system failure.

What You Can Do:

- Never interchange precision parts: Always keep paired parts like injectors and fuel pump elements together throughout their lifespan.

- Mark components during disassembly: Clearly label and track components when servicing the fuel system to avoid accidental mixing.

2. What Happens If Gears in the Drive Axle Main Reducer Are Mismatched?

Problem:

The driving and driven gears in the main reducer of the drive axle are also precision-matched. Interchanging these gears with others can lead to improper alignment, increased wear, noise, and eventual failure of the entire differential assembly.

What You Can Do:

- Maintain original gear pairs: During maintenance or repairs, ensure the driving and driven gears are reinstalled together, as they were originally matched.

- Check for wear: If one gear is worn, it’s best to replace both to maintain their precise alignment and avoid future issues.

3. Why Is It Important to Keep Valves and Hydraulic Steering Components Paired?

Problem:

In hydraulic systems, such as those found in steering systems, components like valve spools and valve sleeves are machined and polished to fit together with high precision. If mismatched or swapped, the hydraulic control may become imprecise, leading to steering difficulties or hydraulic failure.

What You Can Do:

- Reassemble hydraulic components as pairs: Always reinstall valve spools and sleeves as a set to preserve their fit and function.

- Keep track of parts: When disassembling hydraulic components, label and store them carefully to ensure they’re reinstalled correctly.

4. What’s the Risk of Mixing Piston and Cylinder Liners, or Bearings and Journals?

Problem:

After a period of operation, parts like pistons and cylinder liners, bearings and journals, and valves and valve seats become worn together, developing a precise fit. Swapping these parts during repairs can disrupt this fit, leading to poor performance, increased wear, and even engine failure.

What You Can Do:

- Keep worn pairs together: During repairs, maintain the original pairing of components like pistons and liners, bearings and journals, and valves and seats. They should not be mixed with other components.

- Reinstall in the same positions: If possible, put components back in the exact positions they came from during reassembly to preserve their wear patterns.

By carefully managing and maintaining the precision-matched parts of your vehicle, you can ensure optimal performance, reduce wear, and avoid costly breakdowns. Always remember: parts that are meant to work together should stay together!